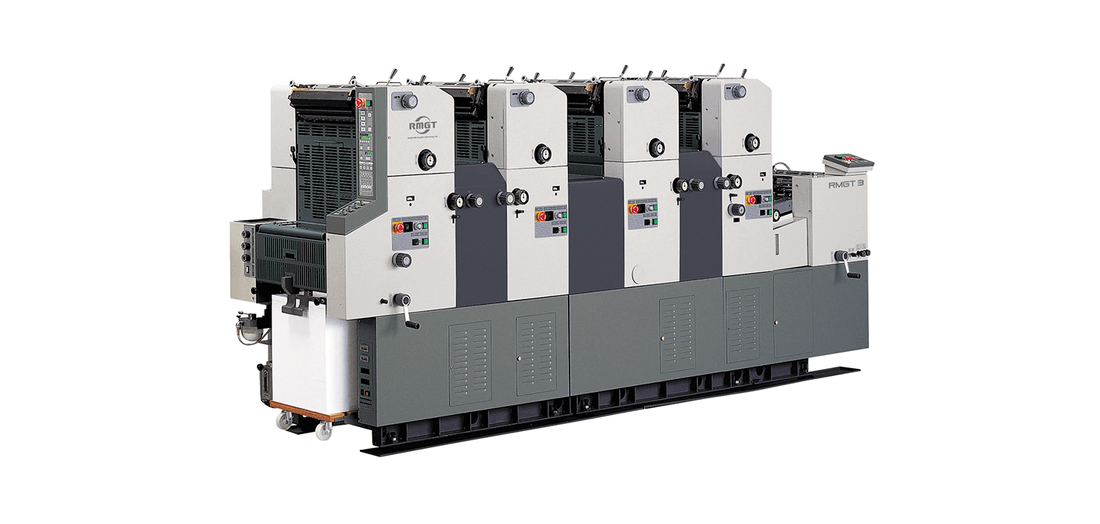

RMGT Offset Presses

Offset Quality - Digital Quantities

All the advantages of offset in today’s digital world.

RMGT Series 11/10

The RMGT 11 Series is a high-throughput, full-size machine able to produce high-quality commercial products, as well as color-dominant short-run jobs with fast make-readies and consistent repeatability.

Download Brochure

RMGT 11 ST (Straight Press)

The RMGT 11 ST (straight press) was developed based on mechanisms offering proven rigidity, an inking device and dampening system that provide exceptional printing quality, and a seven o'clock cylinder arrangement with double-diameter impression and transfer cylinders. This high-performance press boasts the latest state-of-the-art printing technologies.

- SimulChanger fully automatic simultaneous plate changer can change the plates for all units in just 90 seconds

- Easy maintenance, including a function to quickly and easily check the roller nip

- Sheet transfer system's unique air management technology ensures smooth sheet transfer all the way from the feeder to the delivery section

- Multi-mode dampening system switches the dampening mode according to ink coverage required

- Newly developed press information display with a large 55-inch screen enables the operator to easily monitor printing quality and operating status in real time from the delivery section (option)

| Max. printing speed | 15,000 S.P.H. |

|---|---|

| Max. sheet size | 820 x 1,130 mm |

| Min. sheet size | 460 x 620 mm |

| Max. printing area | 810 x 1,120 mm |

| Paper thickness | 0.04 - 0.6 mm |

*Design and specifications are subject to change without notice.

This data was obtained under RMGT's standard test conditions. Results will vary according to the operating conditions.

RMGT 11 LX (Wide stock range press)

The RMGT 11 LX (wide stock range press) features a sheet transfer system that employs unique air management technology and a skeleton transfer cylinder that keeps the surface of the printed sheets from coming into contact with the cylinder. This prevents scratching and smearing, ensuring high printing quality. The lineup also includes models with coating units and curing units to handle high-grade high-gloss printing work.

- Skeleton transfer cylinder keeps surface of printed sheets from coming into contact with cylinder

- Air chamber below transfer cylinder ensures stable sheet transfer for a wide range of sheet thicknesses

- Gripper height adjustment device adjusts the gripper pad height on the transfer cylinder according to the sheet thickness

- Remote controlled ink oscillating rollers dead point positioning (ink light and shade position remote control) and other ink adjustment devices specially for printing on heavy stock (optional)

- Automatic non-stop feeder and delivery shutter boosts productivity for continuous printing on heavy stock (option)

- Delta-type dampening system eliminates the need for hickey removal when printing on heavy stock (option)

- Chamber coater system maintains a consistent coating thickness regardless of printing speed (option)

| Max. printing speed | 15,000 S.P.H. |

|---|---|

| Max. sheet size | 820 x 1,130 mm |

| Min. sheet size | 460 x 620 mm |

| Max. printing area | 810 x 1,120 mm |

| Paper thickness | 0.04 - 1.0 mm |

*Design and specifications are subject to change without notice.

This data was obtained under RMGT's standard test conditions. Results will vary according to the operating conditions.

Available with LED-UV technology.

RMGT 11 TP (Tandem perfector)

The RMGT 11 TP is a unique tandem perfector press on which the reverse-side printing units are connected to a straight printing press via a special translink unit. After printing the reverse side, the front side is printed without reversing the sheets, eliminating various limitations typically associated with perfecting. This also makes it possible to perform perfecting on heavy stock. UV perfecting is also possible by equipping the translink unit with a UV curing unit, providing high-grade printing with no difference in printing quality between the front and reverse sides.

- Special translink unit smoothly transfers sheets from the reverse-side printing units to the front-side printing units without turning the sheets over

- Sheet transfer is performed without changing the gripping side, so plate making position is the same for the front and reverse sides

- Virtually no fan-out, so front and reverse register precision is comparable to that on a straight press

- Configuration can be freely selected from among 1 to 5 reverse-side printing units and 1 to 5 front-side printing units according the job requirements

| Max. printing speed | 13,000 S.P.H. |

|---|---|

| Max. sheet size | 820 x 1,130 mm |

| Min. sheet size | 460 x 620 mm |

| Max. printing area | 810 x 1,120 mm |

| Paper thickness | 0.04 - 0.6 mm |

*Design and specifications are subject to change without notice.

This data was obtained under RMGT's standard test conditions. Results will vary according to the operating conditions.

Available with LED-UV technology.

RMGT 10 ST (Straight press)

The RMGT 10 ST (straight press) was developed based on mechanisms offering proven rigidity, an inking device and dampening system that provide exceptional printing quality, and a seven o'clock cylinder arrangement with double-diameter impression and transfer cylinders. This high-performance press boasts the latest state-of-the-art printing technologies.

- SimulChanger fully automatic simultaneous plate changer can change the plates for all units in just 75 seconds

- Easy maintenance, including a function to quickly and easily check the roller nip

- Sheet transfer system's unique air management technology ensures smooth sheet transfer all the way from the feeder to the delivery section

- Multi-mode dampening system switches the dampening mode according to ink coverage required

- Newly developed press information display with a large 55-inch screen enables the operator to easily monitor printing quality and operating status in real time from the delivery section (option)

| Model | 1020 model | 1050 model |

|---|---|---|

| Max. printing speed | 16,200 S.P.H. | |

| Max. sheet size | 740 x 1,020 mm | 750 x 1,050 mm |

| Min. sheet size | 360 x 540 mm | |

| Max. printing area | 730 x 1,020 mm | 740 x 1,050 mm |

| Paper thickness | 0.04 - 0.8 mm | |

*Design and specifications are subject to change without notice.

This data was obtained under RMGT's standard test conditions. Results will vary according to the operating conditions.

Available with LED-UV technology.

RMGT 10 LX (Wide stock range press)

The RMGT 10 LX (wide stock range press) features a sheet transfer system that employs unique air management technology and a skeleton transfer cylinder that keeps the surface of the printed sheets from coming into contact with the cylinder. This prevents scratching and smearing, ensuring high printing quality. The lineup also includes models with coating units and curing units to handle high-grade high-gloss printing work.

- Skeleton transfer cylinder keeps surface of printed sheets from coming into contact with cylinder

- Air chamber below transfer cylinder ensures stable sheet transfer for a wide range of sheet thicknesses

- Gripper height adjustment device adjusts the gripper pad height on the transfer cylinder according to the sheet thickness

- Remote controlled ink oscillating rollers dead point positioning (ink light and shade position remote control) and other ink adjustment devices specially for printing on heavy stock (optional)

- Automatic non-stop feeder and delivery shutter boosts productivity for continuous printing on heavy stock (option)

- Delta-type dampening system eliminates the need for hickey removal when printing on heavy stock (option)

- Chamber coater system maintains a consistent coating thickness regardless of printing speed (option)

| Model | 1020 model | 1050 model |

|---|---|---|

| Max. printing speed | 16,200 S.P.H. | |

| Max. sheet size | 740 x 1,020 mm | 750 x 1,050 mm |

| Min. sheet size | 360 x 540 mm | |

| Max. printing area | 730 x 1,020 mm | 740 x 1,050 mm |

| Paper thickness | 0.04 - 1.0 mm | |

*Design and specifications are subject to change without notice.

This data was obtained under RMGT's standard test conditions. Results will vary according to the operating conditions.

Available with LED-UV technology.

RMGT 10 TP (Tandem perfector)

The RMGT 10 TP is a unique tandem perfector press on which the reverse-side printing units are connected to a straight printing press via a special translink unit. After printing the reverse side, the front side is printed without the need to reverse the printed sheets, eliminating various limitations typically associated with perfecting. This also makes it possible to perform perfecting on heavy stock. UV perfecting is also possible by equipping the translink unit with a UV curing unit, providing high-grade printing with no difference in printing quality between the front and reverse sides.

- Special translink unit smoothly transfers sheets from the reverse-side printing units to the front-side printing units without turning the sheets over

- Sheet transfer is performed without changing the gripping side, so plate making position is the same for the front and reverse sides

- Virtually no fan-out, so front and reverse register precision is comparable to that on a straight press

- Configuration can be freely selected from among 1 to 5 reverse-side printing units and 1 to 5 front-side printing units according the job requirements

| Model | 1020 model | 1050 model |

|---|---|---|

| Max. printing speed | 16,200 S.P.H. | |

| Max. sheet size | 740 x 1,020 mm | 750 x 1,050 mm |

| Min. sheet size | 360 x 540 mm | |

| Max. printing area | 730 x 1,020 mm | 740 x 1,050 mm |

| Paper thickness | 0.04 - 0.6 mm | |

*Design and specifications are subject to change without notice.

This data was obtained under RMGT's standard test conditions. Results will vary according to the operating conditions.

Available with LED-UV technology.

RMGT 10 PF (Convertible perfector)

The RMGT 10 PF is a convertible perfector press that performs both straight printing and perfecting. A sheet reversing unit installed between the printing units reverses the sheets to enable one-pass perfecting. Switching between straight printing and perfecting is fully automatic and takes just 3 minutes.

- Unique reversing mechanism employing three double-diameter cylinders for fast, high-quality perfecting

- Maintains the same printing speed of 16,000 SPH for both straight printing and perfecting

- Belt transfer guide in the delivery section ensures the belt moves at the same speed as the sheets, preventing scratching of the printed surface

| Model | 1020 model | 1050 model |

|---|---|---|

| Max. printing speed | 16,200 S.P.H | |

| Max. sheet size | 740 x 1,020 mm | 750 x 1,050 mm |

| Min. sheet size | Straight printing: 360 x 540 mm Perfecting: 440 x 540 mm |

|

| Max. printing area | Straight printing: 730 x 1,020 mm Perfecting: 720 x 1,020 mm |

Straight printing: 740 x 1,050 mm Perfecting: 730 x 1,050 mm |

| Paper thickness | 0.04 - 0.6 mm | |

*Design and specifications are subject to change without notice.

This data was obtained under RMGT's standard test conditions. Results will vary according to the operating conditions.

Available with LED-UV technology.

RMGT 9 Series

The RMGT 9 Series A1-size offset press easily handles 8-up A4-size printing at a 6-up price. The 9 Series features a maximum printing speed of 16,200 sheets per hour, varnish coating capability for added value, and offset quality with short run quantities.

RMGT 9 - 940 model

The RMGT 9 series of A1-size offset presses enable high-performance 8-up printing of A4-size. The 940 model has a sheet width of 940 mm. Exceptional features such as a high speed printing and high printing quality make this press ideal for printing companies seeking lower costs, high quality, and high productivity.

- Capable of 8-up printing of international A4 size or letter size

- Significantly lower printing plate costs, power consumption, and space requirements than a B1-size press

- Installation of one LED-UV (or UV) curing unit over the perfecting device and another over the delivery section enables one-pass instant-curing perfecting (920 models only)

- Inline coating system adds value to printed work

- Many of the same features as the flagship RMGT 10, including state-of-the-art sheet transfer technology and a function for quickly and easily checking the roller nip

- Newly developed press information display with a large 55-inch screen enables the operator to easily monitor printing quality and operating status in real time from the delivery section (option)

| Model | ST (straight press) |

|---|---|

| Max. printing speed | 15,000 S.P.H. |

| Max. sheet size | 640 x 940 mm |

| Min. sheet size | 290 x 410 mm |

| Max. printing area | 615 x 930 mm |

| Paper thickness | 0.04 - 0.6 mm |

*Design and specifications are subject to change without notice.

This data was obtained under RMGT's standard test conditions. Results will vary according to the operating conditions.

Available with LED-UV technology.

RMGT 9 - 920 model

The RMGT 9 series of A1-size offset presses enable high-performance 8-up printing of A4-size. The 920 model has a max sheet width of 920 mm. Exceptional features such as a high printing speed of 16,200 S.P.H. and high printing quality make this press ideal for printing companies seeking lower costs, high quality, and high productivity.

- Capable of 8-up printing of international A4 size or letter size

- Significantly lower printing plate costs, power consumption, and space requirements than a B1-size press

- Installation of one LED-UV (or UV) curing unit over the perfecting device and another over the delivery section enables one-pass instant-curing perfecting (920 models only)

- Inline coating system adds value to printed work

- Many of the same features as the flagship RMGT 10, including state-of-the-art sheet transfer technology and a function for quickly and easily checking the roller nip

- Newly developed press information display with a large 55-inch screen enables the operator to easily monitor printing quality and operating status in real time from the delivery section (option)

| Model | St (straight press) | PF (convertible perfector) |

|---|---|---|

| Max. printing speed | 16,200 S.P.H. | 13,000 S.P.H. |

| Max. sheet size | 640 x 920 mm | Straight printing: 640 x 920 mm Perfecting: 635 x 920 mm |

| Min. sheet size | 290 x 410 mm | Straight printing: 290 x 410 mm Perfecting: 370 x 410 mm |

| Max. printing area | 615 x 900 mm | |

| Paper thickness | 0.04 - 0.6 mm | 0.04 - 0.4 mm |

*Design and specifications are subject to change without notice.

This data was obtained under RMGT's standard test conditions. Results will vary according to the operating conditions.

Available with convertible perfector and LED-UV technology.

RMGT 7 Series

The RMGT 7 Series offers a wide range of unit configurations to meet specific customer needs for a high-productivity, high-profitability printing and packaging environment.

RMGT 7 - 790 model

The 790 models can be configured according to customer needs, providing the optimum printing environment for increasing productivity and profitability. A highly reliable mechanism featuring the latest technologies and advanced automation devices, combined with a digital-controlled printing control system, ensures high-speed, high-quality printing.

- Easily handles 8-up printing of B5 size

- Double-diameter transfer cylinder for stable sheet transport

- Program inking, automatic plate changing system, various preset devices, and other automation systems significantly shorten make-ready

- Incorporating V-type feeder, the same high performance feeder as RMGT 10 series

- Fully automatic convertible perfecting device capable of one-pass perfecting

- Thick cardboard specification model handles sheet thicknesses up to 0.8 mm (option)

- An IR, UV, or LED-UV curing unit can be installed at the delivery section (option)

| Model | ST (straight press) | PF (convertible perfector) |

|---|---|---|

| Max. printing speed | 16,000 S.P.H. | 15,000 S.P.H. |

| Max. sheet size | 600 x 788 mm | |

| Min. sheet size | 290 x 410 mm [ option: 200 x 279 mm ] | |

| Max. printing area | 790ST-S(PF-S): 545 x 765 mm 790ST-XL(PF-XL): 580 x 765 mm |

|

| Paper thickness | 0.04 - 0.6 mm (Thick cardboard specification: 0.04 - 0.8 mm) |

Straight printing: 0.04 - 0.6 mm Perfecting: 0.04 - 0.4 mm |

*Design and specifications are subject to change without notice.

This data was obtained under RMGT's standard test conditions. Results will vary according to the operating conditions.

Available with convertible perfector and LED-UV technology.

RMGT 7 - 760 model

The 760 models boast excellent cost performance to meet printing market needs for lower costs. The maximum printing area is large enough to easily handle 8-up printing of B5 size, and integration of the operation stand into the press reduces installation space.

- Double-diameter impression cylinder and double-diameter transfer cylinder ensure stable sheet transport even when printing on heavy stock

- Excellent cost performance, with many of the same features as the 790 models

- Easily handles 8-up printing of B5 size

- PCS-K printing control system is built right into the press for a compact footprint

| Model | ST (straight press) | PF (convertible perfector) |

|---|---|---|

| Max. printing speed | 13,000 S.P.H. | |

| Max. sheet size | 600 x 765 mm | |

| Min. sheet size | 200 x 279 mm | Straight printing: 200 x 279 mm Perfecting: 295 x 325 mm |

| Max. printing area | 760ST-S(PF-S): 545 x 765 mm 760ST-XL(PF-XL): 580 x 765 mm |

|

| Paper thickness | 0.04 - 0.6 mm | Straight printing: 0.04 - 0.6 mm Perfecting: 0.04 - 0.4 mm |

*Design and specifications are subject to change without notice.

This data was obtained under RMGT's standard test conditions. Results will vary according to the operating conditions.

RMGT 5 Series

The RMGT 5 Series is generously equipped with high-end technologies in order to flexibly meet the demand for a wide range of printing jobs. This offset press represents more than 10,000 units sold worldwide.

RMGT 5 - 520GX model

The 520GX includes an array of high-end technologies, offering high-speed printing at up to 15,000 S.P.H. and numerous automation and labor-saving devices. The 520GX can easily handle a wide range of printing work, from catalogs and cardboard packages to envelopes and postcards.

- Satellite-type cylinder arrangement consists of a double-diameter impression cylinder and double-diameter and triple-diameter transfer cylinders

- SPC semiautomatic plate changer ensures fast, accurate plate changing (standard equipment)

- Vacuum feeder board for easier setting of the brush and runner wheels and faster changing of the sheet size

- Prints laterally fed postcards and envelopes

- Fully automatic convertible perfecting device (520GXP)

- 5-color and 6-color printing and inline varnish coating for high value-added printing

| Model | GX (straight press) | GXP (convertible perfector) |

|---|---|---|

| Max. printing speed | 15,000 S.P.H. | |

| Max. sheet size | 375 x 520 mm | |

| Min. sheet size | 105 x 100 mm | Straight printing: 105 x 100 mm Perfecting: 150 x 100 mm |

| Max. printing area | 350 x 505 mm | |

| Paper thickness | 0.04 - 0.6 mm | Straight printing: 0.04 - 0.6 mm Perfecting: 0.04 - 0.4 mm |

*Design and specifications are subject to change without notice.

This data was obtained under RMGT's standard test conditions. Results will vary according to the operating conditions.

Available with convertible perfector and LED-UV technology.

RMGT 5 - 520GE model

The 520GE has a variety of automation and labor-saving devices for "smart" operation and exceptional printing quality. Various optional devices are also available as upgrades, including the PCS-JX printing control system and cleaning devices. This 2-color press delivers high performance for short-run color printing at a low cost.

- SPC semiautomatic plate changing system for fast, accurate plate changing (standard equipment)

- PCS-JX printing control system for remote adjustment of ink keys (option)

- Vacuum feeder board for easier setting of the brush and runner wheels and faster changing of sheet size

- Prints laterally fed postcards and envelopes

- Rotary-type stream feeder ensures stable sheet supply, from thin sheets to heavy stock

| Max. printing speed | 11,000 S.P.H. |

|---|---|

| Max. sheet size | 375 x 520 mm |

| Min. sheet size | 105 x 100 mm |

| Max. printing area | 350 x 505 mm |

| Paper thickness | 0.04 - 0.4 mm (0.5)mm 0.5 mm stock can be printed when feeding sheets perpendicular to the fiber direction. |

*Design and specifications are subject to change without notice.

This data was obtained under RMGT's standard test conditions. Results will vary according to the operating conditions.

Available with LED-UV technology.

RMGT 5 - 520HX model

The 520HX is equipped with the R-matic continuous dampening system. The highly reliable mechanism and simple operation ensure high productivity and high printing quality, making it the ideal A3-plus-size single-color press for short-run printing.

- Underswing and drop away infeed system maintains high register precision even at high speeds

- Front/side lay register controller enables the register to be quickly set by push button operation to adjust the front lay and side lay

- Straight-edge clamp with a register pins and quick tension mechanism enable quick plate changing

- Rotary-type stream feeder ensures stable sheet supply, from thin sheets to heavy stock

| Max. printing speed | 13,000 S.P.H. |

|---|---|

| Max. sheet size | 375 x 520 mm |

| Min. sheet size | 105 x 100 mm |

| Max. printing area | 350 x 505 mm |

| Paper thickness | 0.04 - 0.4 mm (0.5)mm 0.5 mm stock can be printed when feeding sheets perpendicular to the fiber direction. |

*Design and specifications are subject to change without notice.

This data was obtained under RMGT's standard test conditions. Results will vary according to the operating conditions.

Available with LED-UV technology.

RMGT 3 Series

The RMGT 3 Series is an A3-size portrait format offset press designed to meet market needs for multiple colors and digitalization. Using a satellite V-shaped five-cylinder arrangement, the body of the press takes up only 3.8 square meters of floor space. This offset press can easily handle PS, polyester-based, and other plate materials for economical four-color printing.

RMGT 3 - 340HA-4 model

The 340HA-4 A3-size portrait format 4-color press was developed to meet market needs for color printing and digitalization. It is the ideal response to the growing demand for multi-color short-run printing work.

- Space-saving 4-color press requires just 3.8 m2 of installation space

- The satellite-type cylinder arrangement consists of a double-diameter impression cylinder and double-diameter and triple-diameter transfer cylinders

- Equipped with the SPC semiautomatic plate changer for fast, accurate plate changing (standard equipment)

- SuperDampener continuous dampening system maintains an ideal aqua film of dampening solution on the plate surface right from startup

- PCS-F printing control system includes an operation stand for remote adjustment of the ink fountain keys

| Max. printing speed | 10,000 S.P.H. |

|---|---|

| Max. sheet size | 450 x 340 mm |

| Min. sheet size | 100 x 90 mm |

| Max. printing area | 438 x 330 mm |

| Paper thickness | 0.04 - 0.3 mm |

*Design and specifications are subject to change without notice.

This data was obtained under RMGT's standard test conditions. Results will vary according to the operating conditions.

RMGT 3 - 340HA-2/340C-2 models

The 340HA-2 and 340C-2 presses provide flexible, economical, multi-color printing. They are ideal for meeting the growing demand for short-run color printing of postcards, leaflets, direct-mail advertisements, envelops, etc.

- Satellite-type cylinder arrangement employed, consisting of a double-diameter impression cylinder and double-diameter and triple-diameter transfer cylinders

- SPC semiautomatic plate changer provides fast, accurate plate changing (340HA-2 only)

- Crestline continuous dampening system for easy adjustment of the dampening film (340C-2 only)

- Paper feed cylinder diagonal image adjustment and dial-controlled image position adjustment

- Lever-controlled ink fountains for easy fine color adjustment (option)

- PCS-F printing control system includes an operation stand for remote adjustment of the ink fountain keys (option)

| Max. printing speed | 10,000 S.P.H. |

|---|---|

| Max. sheet size | 450 x 340 mm |

| Min. sheet size | 100 x 90 mm |

| Max. printing area | 438 x 330 mm |

| Paper thickness | 0.04 - 0.3 mm |

*Design and specifications are subject to change without notice.

This data was obtained under RMGT's standard test conditions. Results will vary according to the operating conditions.

RMGT 3 - 340CR-1 model

340CR-1 is equipped with a 16-roller inking system including 3 form rollers to guarantee beautiful reproduction of halftones and solid colors. The registration device and the optional second color head make this press well-suited for multi-color jobs.

- Straight-edge clamp with register pins securely grips the plate

- Push side guide register device accurately positions sheets on the feeder board

- Crestline continuous dampening system for easy adjustment of the dampening film

- Single-lever operation for plate dampening, inking to imaging, sheet feed, and printing

- Original second color head available as an economical option for multi-color printing (option)

| Max. printing speed | 10,000 S.P.H. |

|---|---|

| Max. sheet size | 450 x 340 mm |

| Min. sheet size | 140 x 90 mm |

| Max. printing area | 438 x 330 mm |

| Paper thickness | 0.04 - 0.3 mm |

*Design and specifications are subject to change without notice.

This data was obtained under RMGT's standard test conditions. Results will vary according to the operating conditions.

RMGT 3 - 340PCX-2 model

The 340PCX-2 is an A3-size blanket-to-blanket type perfecting press embodying RMGT's wealth of expertise in small offset presses. With a variety of automation and labor-saving devices, lever-less printing operation, and controls concentrated at the delivery section, the 340PCX-2 provides exceptional ease of operation.

- One-button easy operation for the entire series of printing steps: from master insertion, image transfer, sheet feed and printing to master ejection, blanket cleaning and drying

- Inverter control and pushbutton operation allow continuously variable adjustment of the printing speed from 3,000 to 10,000 S.P.H.

- Blanket-to-blanket type perfecting press on which sheets pass between 2 blanket cylinders

- Crestline continuous dampening system for easy adjustment of the dampening film

- Wide printing area of 438 x 317 mm easily handles printing of cover stock

- Blanket cleaning device with cleaning solution circulation system (option)

| Max. printing speed | 10,000 S.P.H. |

|---|---|

| Max. sheet size | 450 x 340 mm |

| Min. sheet size | 130 x 90 mm |

| Max. printing area | 438 x 317 mm |

| Paper thickness | 0.04 - 0.3 mm |

*Design and specifications are subject to change without notice.

This data was obtained under RMGT's standard test conditions. Results will vary according to the operating conditions.

RMGT 3 - 340CCD-1 model

The 340CCD-1 A3-size portrait-format single-color press was specifically developed to provide high productivity and easy operation. The Crestline continuous dampening system enables easy, stable adjustment of the dampening film. This press can flexibly handle a wide range of short-run printing work.

- Switches and other controls are concentrated on the easy-to-use swivable operation panel

- Maximum printing area of 438 x 330 mm enables easy printing of cover stock and imposition printing, including register marks

- Dial-type vertical image fine adjustment control allows simple and accurate adjustment of the image position

- A photoelectric impression pressure setting device ensures stable sheet feed, from thin sheets to heavy stock

- Inverter control and pushbutton operation allow continuously variable adjustment of the printing speed from 3,000 to 10,000 S.P.H.

| Max. printing speed | 10,000 S.P.H. |

|---|---|

| Max. sheet size | 450 x 340 mm |

| Min. sheet size | 130 x 90 mm |

| Max. printing area | 438 x 330 mm |

| Paper thickness | 0.04 - 0.3 mm |

*Design and specifications are subject to change without notice.

This data was obtained under RMGT's standard test conditions. Results will vary according to the operating conditions.

LED-UV Technology

RMGT LED-UV Instant Curing

The RMGT LED-UV Perfector is an available option on all RMGT offset presses. The LED-UV Perfector dries printed sheets instantly, and offers impressive energy savings with superior ease of use. This system greatly reduces energy consumption and also features a much longer lifespan than conventional lamp perfecting systems. The LED-UV Perfector is completely powderless and produces zero ozone pollution, making it very eco-friendly.

LED-UV Advantages

SHORTER LEAD TIMES

- With no need to wait for printed sheets to dry, work can immediately move on to subsequent processes

- No space is needed to store printed sheets while they dry

ENVIRONMENTALLY FRIENDLY

- Powderless printing ensures a cleaner work environment

- LED-UV ink is recyclable and easily removable

- Lower energy consumption leading to reduced CO2 emissions

- Birmingham Printing's Commitment To Environment-Friendly Print

CONSISTENT PRINT QUALITY

- No set-off, so printed sheets can be stacked immediately after printing

- No color changes due to dry-down

- No problem with powder dropping on to printed sheets

COMPATIBLE WITH SPECIAL MEDIA

- Printing is possible on resin film, synthetic paper, metalized paper, and other types of special media

GREATLY REDUCED POWER CONSUMPTION

- LED-UV uses 1/8th of the power a conventional UV lamp system needs

- Light source can be instantly switched on/off to suit the operating status, reducing power consumption during job turnover

NO OZONE SMELL

- No need to install deodorizing equipment or exhaust ducts

- LED-UV systems can be used in congested areas

NO INFRARED LIGHT

- LED-UV perfectors produce no infrared light, so the unit generates much less heat

- Printed sheets do not shrink due to heat

- The LED-UV system is compatible with resin film and other media

LONG LIFE

- Conventional UV Lamp Systems = 1,000 to 3,000 lifetime hours

- LED-UV Systems = 15,000 lifetime hours

- UV lamp systems must remain lit during job changeover, the LED-UV system can be switched off